A gas furnace has several components that function in a precise sequence to provide heat. The first part of the process is the thermostat. When a homeowner flips the switch on their thermostat, 24 volt power is already present at the R terminal of the stat, which closes the W terminal of the thermostat. A signal from the thermometer is sent to a control board in the furnace. This control board contains switches, resistors, and terminals that operate in a certain order. It is the quarterback of the heating system.

Once the system is turned on, a thermostat will turn on the furnace and allow the gas to flow through the system. A blower fan will help push this heat out through the air ducts. As with any other heating system, the process of combustion is similar to that of a car’s internal combustion engine. The engine then burns fuel to produce heat, which pushes pistons. The ignition switch is the key component of the system.

A gas furnace’s ignitor causes combustion. This combustion takes place in the engine’s chamber, which holds the fuel. Once the fuel is mixed with oxygen, it travels through the system’s ducts. The resulting heat is then pushed out through the air ducts. The process is similar to that of an internal combustion engine. The energy generated from the combustion burns the fuel and pushes pistons.

A gas furnace’s ignition is triggered by the thermostat. A low-voltage electrical signal is sent to the ignitor, which opens a valve and delivers the natural gas to the burners. The pilot light, or electronic ignition, ignites the gas in the combustion chamber. A flame detector is designed to detect if there’s a buildup of gas, so if the ignition is failing, it shuts off the gas.

The ignitor lightens the gas. It ignites the gas by passing it over a metal or PVC pipe. A fan, or blower, pushes the hot air out through the ducts. The ignitor is an important part of a gas furnace because it controls the flow of gas through the cabinet. It also controls the amount of heat that passes through the cabinet. Gas Line Repair in San Fernando Valley

The burners release heat energy. This energy is transferred to the lungs through the exhaust. An ignitor lights the gas by drawing it into a metal or PVC pipe. The exhaust is pushed into the atmosphere via a roofline. It is similar to the internal combustion engine in a car. As fuel burns in the engine, it generates heat and pushes the pistons.

The ignitor lightens the gas by drawing it through the ducts. The ignitor is the part of a gas furnace that lights the flame. The ignitor draws the gas into the pipe and transfers it into the atmosphere. The ducts in the furnace will then allow the air to reach the room. After this, the exhaust is pushed out to the outdoors through a roofline and out the chimney.

The combustion process in a gas furnace produces heat energy. The fuel is the natural gas. This fuel is then burned in the furnace and the heat is then expelled through the air ducts. It is akin to the internal combustion engine of a car, where fuel is burned to generate energy. During this process, a small spark is generated and the gas is ignited. This fire is caused by a super-hot surface.

A gas furnace has two main types of ignitors. The first type is the pilot light, which contains a small gas flame. The second type is the electric heat source ignitor. The latter uses a metal rod that is heated to 1,800 degrees to ignite the gas. The final part is the combustion chamber, which is where the fuel and oxygen mix. If the sparks are not lit, the furnace will not burn.

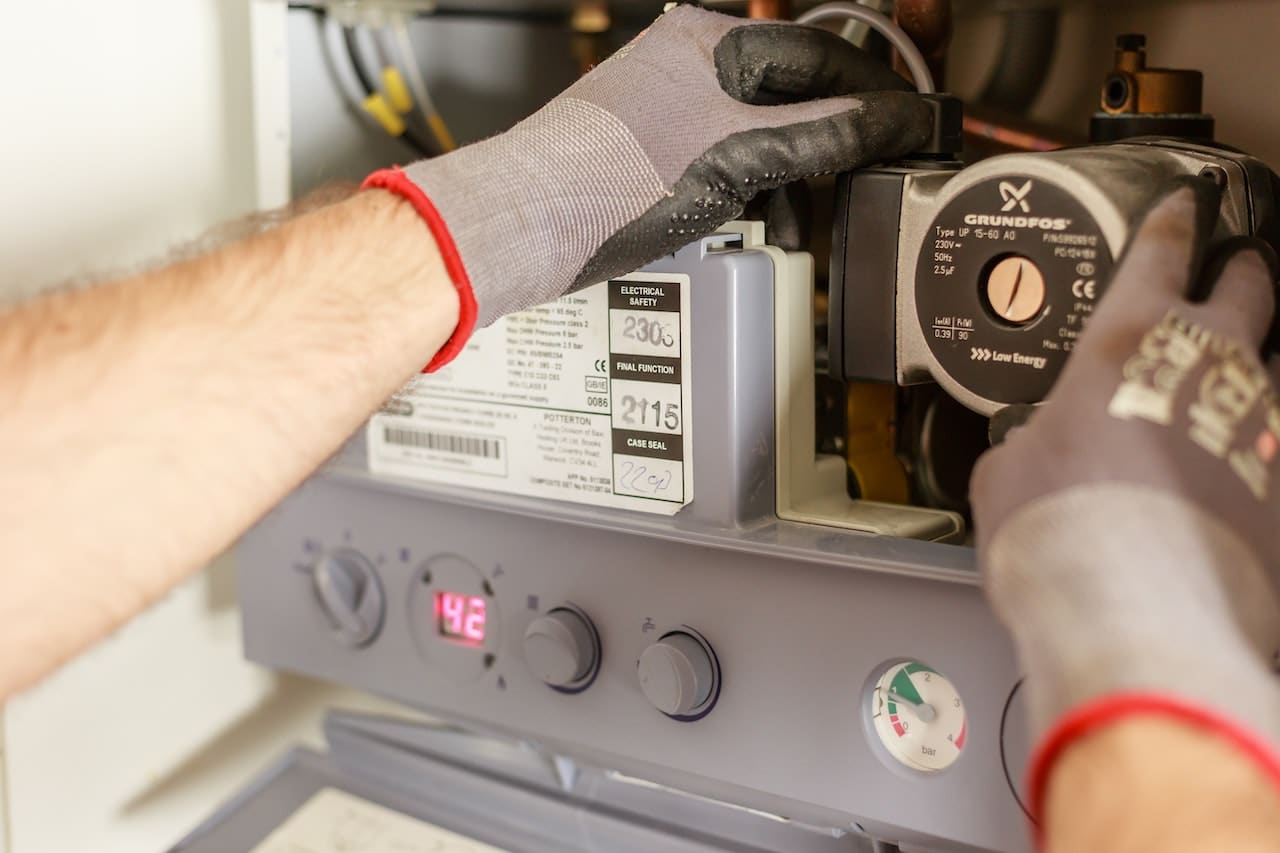

Today’s gas furnaces require electricity to ignite the burners. Standing pilot lights have been replaced with electronic ignition systems that make the system safer and more energy-efficient. The electrical components of gas furnaces also keep the system safe. An overloaded furnace will trip its circuit breaker, which can lead to dangerously high temperatures. However, modern-day gas furnaces are safer, more efficient, and more reliable than their predecessors.